A forklift fork grabber for securing attachments to a forklift comprising: a fork attachment base comprising two fork tubes for receiving forks, each of the fork tubes defining an aperture on an interior surface facing the opposing fork tube of the fork tube for facilitating engagement between a fork of said forks and a hydraulically-actuated cylinder and the hydraulically-actuated cylinder for applying tensile force to the forks. The forklift fork grabber of claim 1, wherein each of the fulcrum mounts is welded to said interior surface of the fork attachment base.Ĥ. The forklift fork grabber of claim 1, further comprising a tapered engagement protrusion affixed to a distal end of a lever of said two levers.ģ.

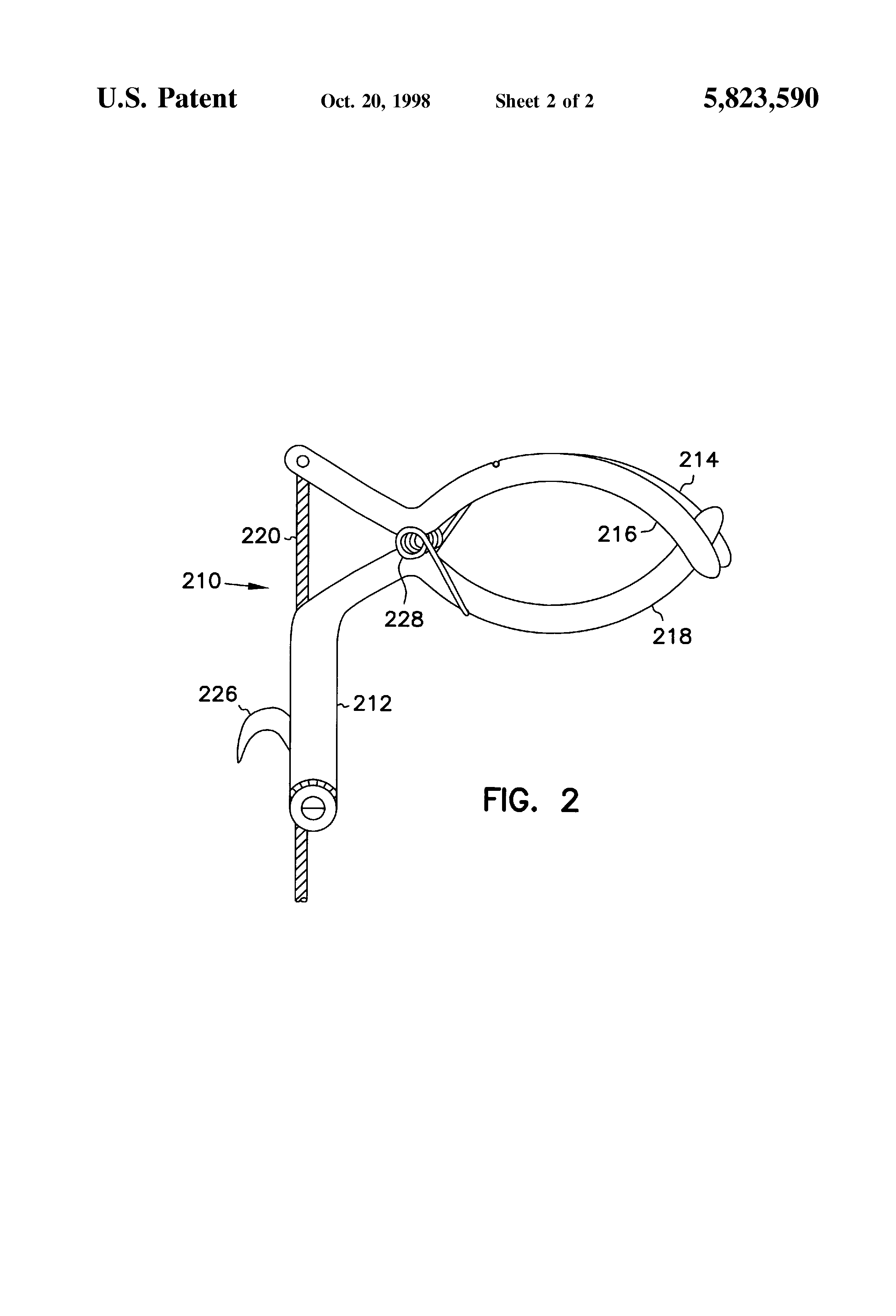

A forklift fork grabber for securing attachments to a forklift comprising: a fork attachment base comprising two fork tubes for receiving forks, each of the fork tubes defining an aperture on an interior surface of the fork tube which faces an opposing fork tube for facilitating engagement between a fork and the forklift fork grabber two fulcrum mounts, each of the two fulcrum mounts affixed to an interior surface of a fork tube of said fork tubes a binder for applying tensile force with ratcheting of a handle two levers, each lever hingedly affixed at a midpoint to a fulcrum mount of said fulcrum mounts, each lever hingedly affixed at a proximal end to the binder and wherein each lever is adapted to apply tensile force at a distal end through said aperture to the fork inserted into a fork tube of said fork tubes when the binder is ratcheted such that the fork becomes frictionally bound to the fork attachment base.Ģ.

0 kommentar(er)

0 kommentar(er)